History

The Harry Childs was built on a Halmatic Pacific 32 hull, designed for the Royal Navy, and supplied as a bare hull and collar for finishing by the then Lifeboat Operations Manager and Marine Engineer, Colin Olden MBE. The boat was launched in 1995.

Following a successful 10 years in service, during which the engines clocked up about 2000 hours, we had an opportunity to change the engines, and the boat was generally refurbished. During the following 10 years, the boat continued to give good service, but towards the end of that period, we experienced several failures that indicated that a major refit would be required. Unfortunately, while on its river mooring during a winter storm, the newer of our P32 boats, the John & Violet Hurrell, took on a lot of water, and required extensive work to repair, including fitting two new engines. This coincided with the start of the build of our new boathouse, all of which meant that the Harry Childs refit was delayed by about 2 years.

Sizing the project

We recovered the Harry Childs into our new boathouse in September 2017. The event was precipitated by the failure of an engine coolant hose, a starter motor, and water in one of the jet drive gearboxes, and the newer boat was almost ready for launch. Therefore, before we recovered the boat, it was clear that certain work would be required:

- The engines were due an 800-hour service, and well as replacing the failed parts, and there was a coolant leak on the oil cooler

- The jet gearboxes needed a major overhaul. Two years previously, a bearing had failed on the impeller shaft, and we fitted another as a temporary measure while the boat was held in the slings at Deacons Boatyard. We thought that might have been responsible for the water in the gearbox

- The Collar was worn in some areas. We thought that it might be patched.

- The radar had failed, and since it was believed to be beyond economic repair, we decided to replace that and the navigation system with the Furuno system we had taken from the newer boat during its refit. Although old, it was still more modern than the system on the Harry Childs.

- The console, gantry, seats, towing horse, engine box, and deck all needed to be refurbished.

- The old anti-fouling needed to be removed, the hull inspected, and any gel-coat scratches repaired, before re-coating in underwater primer and anti-fouling paint.

The most expensive single item was likely to be the jet gearboxes, for which we budgeted £10000, but the cost of everything else mounts up, even without labour, and we budgeted £30000 to complete. The aim was to have the boat back in service in the Spring of 2018, at which time the newer boat would require attention.

Once in the boathouse, we set about stripping the boat and doing a proper appraisal of the work required. There was an immediate stumbling block; on closer examination of the collar, it was clear that if we repaired it, it would end up more patch than collar! Fortunately, Henshaw Inflatables of Wincanton still had the templates for the J&V Hurrell’s collar, as supplied to Halmatic. By a stroke of luck, a generous benefactor, who wished to remain anonymous, donated almost the amount we needed that very week.

We removed the jets, and Marlin Marine of Southampton collected them to strip down and assess what needed to be replaced. About a week later we got a list of parts, which we costed online at about £9000, plus the labour, so it appeared that our initial estimate wasn’t far out! However, Marlin also reported that the castings weren’t in great shape. They could repair them, but couldn’t guarantee how much life they would have, and we were looking for at least 5 years to the next refit. The jets, being 20 years old, are out of production, and replacing them with a different type has many implications, not least being extensive modifications to the hull. However, when we contacted Castoldi in Italy, they said they could build us two units. So, working with their agents, Lancing Marine in Shoreham, we bit the bullet and ordered two new jets. The cost of new jets was nearly twice the cost of repair, but that way we were in a better position.

Planning

We used Microsoft Project to build a plan. Initially, this showed that it was theoretically feasible to complete the project by Spring, and the plan shows that we should have been finished in April. However, the plan called for about 500 hours of labour, and the timescale assumed people working full-time. In practice, labour was to be supplied by volunteers working part-time, and it was clear that the work would inevitably fall to a small number of volunteers with the required skills, so the overall timescale would be determined by their availability. Nevertheless, having a plan did mean that things tended to get done in the right order.

Design

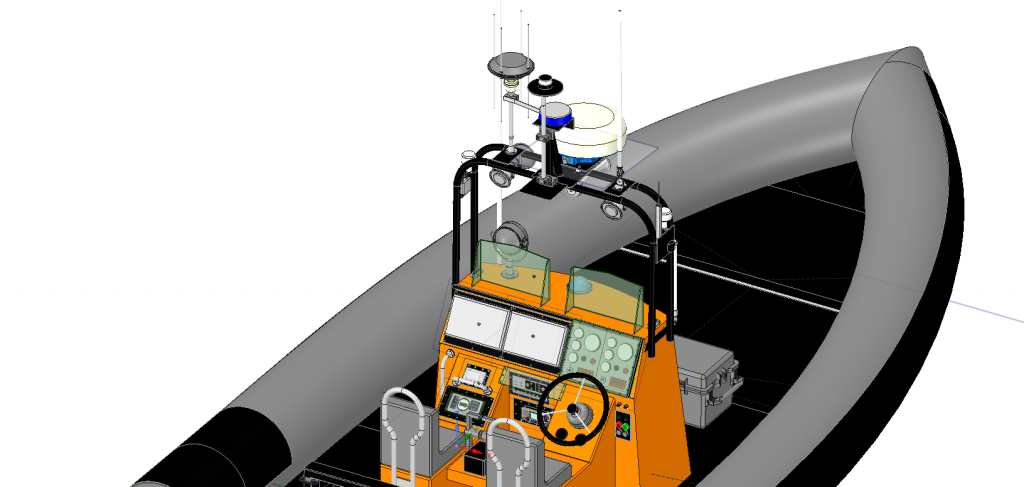

Nothing is ever as one would like it to be. The simple statement “replace the radar” required extensive modifications to the console to allow the displays to fit, and that also meant that other equipment had to be relocated. The radar scanner was, of course, a different size, and space for additional aerials on the gantry was at a premium. There were a few other improvements that we wanted to make along the way; fitting LED navigation lights, a Radar Target Enhancer, an additional electric bilge pump, and updated bilge and exhaust temperature alarms are some examples.

Before drilling and cutting, we made a 3D model of the new layout to make sure everything was going to fit, and more importantly to check that once built, we could get it under the boathouse door!

Work in progress

Henshaws fitted the new collar in December; the new jets were delivered in March, and are awaiting fitment, but first we need to withdraw the prop-shafts to check and lubricate the CV joints. It will also be a lot easier to clean the bilge and fit the bilge pumps before putting the jets back.

We removed the gantry and sent it to Trestan Finishers in Southampton to have it professionally shot-blasted and re-painted. That has been re-fitted, with all the aerials and lights. The console layout has been modified, and re-painted, and wiring is under way.

Unfortunately, the towing horse was showing signs of corrosion, and being a load-bearing structure, we decided to replace it. STS Defence at Gosport kindly welded up a new one for us.

Replacing and painting the deck isn’t an onerous task, but It will be easier to check the engines, fit new starter motors, and do the 800-hour service while the engine box is off the boat being refurbished, and the aft deck is removed. However, the task of removing the anti-fouling proved to be quite difficult. We have a quote to have it done professionally by Deacons Boatyard, and we are considering whether we can afford that.

Overall, with the new collar, and new jets, and allowing for a professional job on the hull, the Service isn’t going to see much change out of £40000. We have logged about 280 volunteer hours so far working directly on the boat, and an estimated 120 hours on designing, planning, purchasing, etc. At the end, the original 500-hour estimate will not be far from the mark. We will have a boat that is sound, and will hopefully give good reliable service until its next refit in 5 years’ time.

Of course, none of this would be possible without the generosity of our benefactors, and the support of local business, only some of which have been mentioned above.

FAQ’s

Q. How much would a new boat cost?

A. In 2004, the hull, engines, jets, and electronics for the John & Violet Hurrell cost about £200,000, which is £290,000 in today’s money, not including the labour given freely by volunteers. Today, the Halmatic Pacific 32 hulls are no longer made, Halmatic having been taken over by Vosper Thorneycroft, but the Halmatic brand is continued now by BAE Systems. The nearest equivalent is the Pacific 950, which can be produced in a variety of configurations. If we were to buy one complete to our specification, the budget would be around £500,000.

Q. How much would it cost to replace the old radar and navigation system?

A. We received a generous donation from Southampton Round Table towards the cost of a new Furuno NXT system, which we fitted to the Lifeboat John & Violet Hurrell last year. The total cost of the system was about £8000.